THE ESTA ATEX PROGRAMME AND FIRE PROTECTION CONCEPT - FOR A SAFE WORKPLACE

There is a risk of fire and explosion in all industrial installations in which flammable and explosive dusts occur.

Frequently the mistake is made of considering and evaluating the two terms "fire hazard" and "explosion hazard " together. Of course, there are certain influences common to each, but in planning and design they have to be treated separately , because fire protection measures do not prevent an explosion - and vice versa.

We would therefore like to explain the terms "fire" and "explosion" separately here.

FIRE PROTECTION

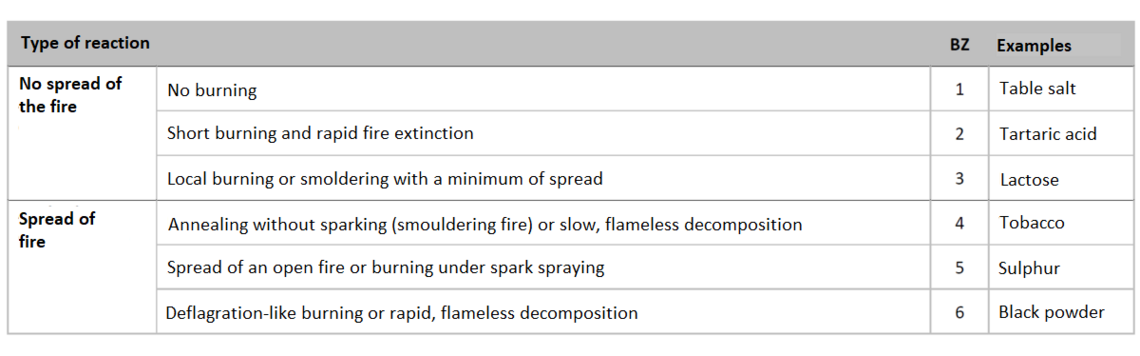

A decisive indicator of the possible flammability of a dust and the spread of a fire is the combustion factor. This is classified as follows:

You can find out about the combustion factor from EX Gestis or via a substance analysis that we can carry out for you.

We can offer the following extinguishing options:

- ABC powder extinguishing (possibly D for metals)

- CO2 extinguishing

- Argon extinguishing

- Water extinguishing

ESTA has developed a three-stage safety concept which we tailor individually with the customer. For customer requests that deviate from the concepts, we advise and plan requirements and show the corresponding benefits and disadvantages in advance.

Corresponding decision-making aids for a safety concept can be found in standards VDI 2263 Part 6 and VdS 3445, among others.

EXPLOSION PROTECTION

If you talk about explosion protection, you are very likely to hear the term ATEX. ATEX stands for Atmosphères Explosibles.

Explosion protection is regulated by the ATEX directive, which is divided into the ATEX Product Directive 2014/34/EU and the ATEX Operating Directive 1992/92/EC.

The term "explosion" is understood to mean a chemical reaction or a physical process in which temperature and pressure increase considerably in a very short time (a few milliseconds). A sudden volume expansion of gases occurs, along with the release of large amounts of energy in a small space.

The sudden release of energy causes a pressure wave that expands in all directions, whilst weakening. The pressure wave is overtaken after a certain time by the flame front (deflagration).

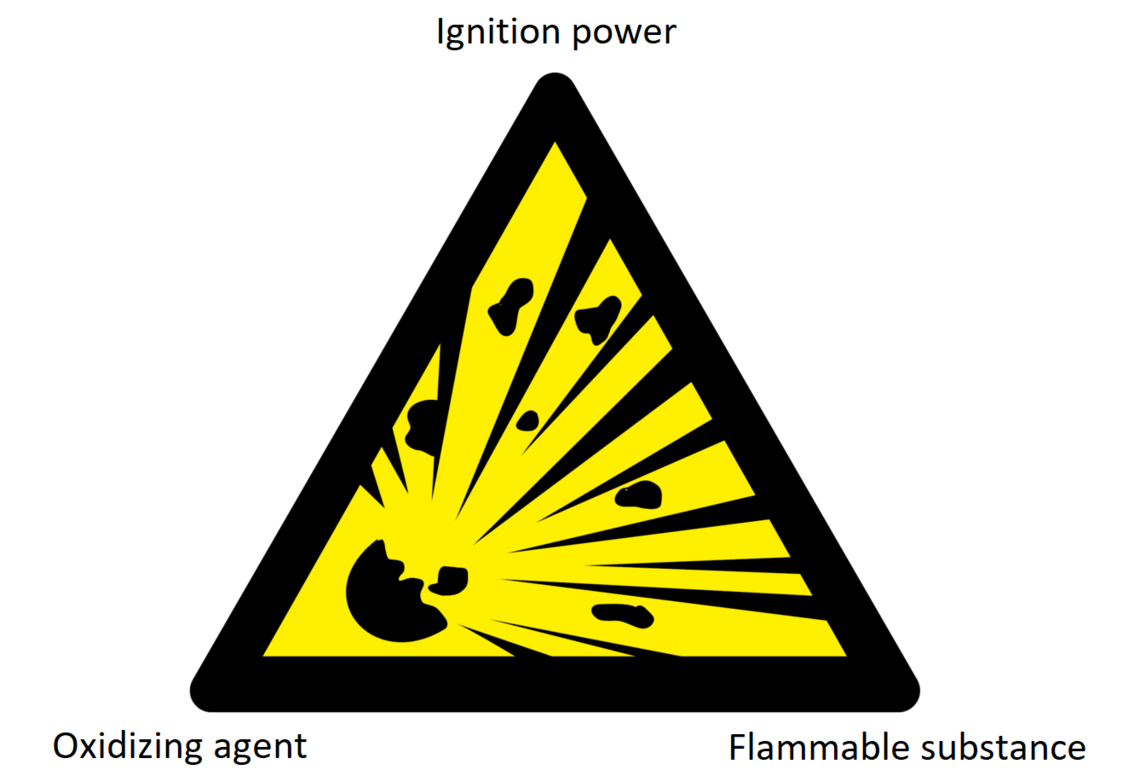

The prerequisite for an explosion is what is called the "explosion triangle ".

ATEX EXTRACTION SYSTEMS

There is a risk of explosion in all extraction systems in which flammable dusts occur. Under certain conditions an explosive mixture forms in these "Ex-areas" in connection with air. A small spark (e. g. due to static charge) is sufficient to cause a dust explosion.

To ensure that our extraction systems can be configured for explosion protection and ATEX extraction, certain parameters must be known. These include, for example:

- The minimum ignition energy (MIE)

- Explosion limits (LEL / UEL)

- Dust explosion class Kst value

- Grain size

ATEX ZONES

In addition, the extraction system is divided into zones. Here a differentiation must be made between gases and dusts.

This is the area where a hazardous explosive atmosphere exists as a mixture of air and flammable gases, vapours or mists, constantly, for long periods of time or frequently.

Area where, during normal operation, a hazardous explosive atmosphere may occasionally be created as a mixture of air and combustible gases, vapours or mists.

Area where, during normal operation, a hazardous explosive atmosphere as a mixture of air and combustible gases, vapours or mists normally cannot form, or only rarely and for a short time.

Area where a dangerous explosive atmosphere in the form of a cloud of combustible dust contained in the air is constantly present, is present frequently or over lengthy periods.

Area where, during normal operation, a dangerous explosive atmosphere may occasionally be created in the form of a cloud of combustible dust contained in the air.

Area where, during normal operation, a dangerous explosive atmosphere in the form of a cloud of combustible dust contained in the air cannot normally form, or only rarely and briefly.

EXPLOSION PROTECTION MEASURES

- Ignition hazard assessment

- Check valves

- Flameless pressure relief

- Explosion suppression systems

- System components electrically conductive throughout

- Explosion pressure or explosion pressure shock resistant construction of apparatus

- Creation of an explosion protection document

We perform our services according to the following legal principles:

- Technical Rules for operational safety (TRBS), e. g. TRBS 1201 part 1

- Technical Rules for hazardous substances (TRGS), e. g. TRGS 510 and TRGS 509

- TRGS 500 "Protective measures"

Do not put yourself and your environment in unnecessary danger! Get ahead with safety - with ATEX-compliant products from ESTA. Our sales consultants work with you to find the right solution. Just contact us!

SUITABLE PRODUCTS

CONTACT

WE ARE HAPPY TO PROVIDE A PERSONAL CONSULTATION

We can adapt our exhaust installations to your needs. Tailor-made, modular and individual. Ask us!