HOW IS A CENTRAL EXTRACTION SYSTEM BUILT?

WHEN DO I NEED A CENTRAL EXTRACTION SYSTEM?

This question is frequently asked in consulting sessions. To clarify it, we need to take a closer look at the functions and application options of a central extraction system. To find out if a central extraction system is the right solution, the components should be considered in detail.

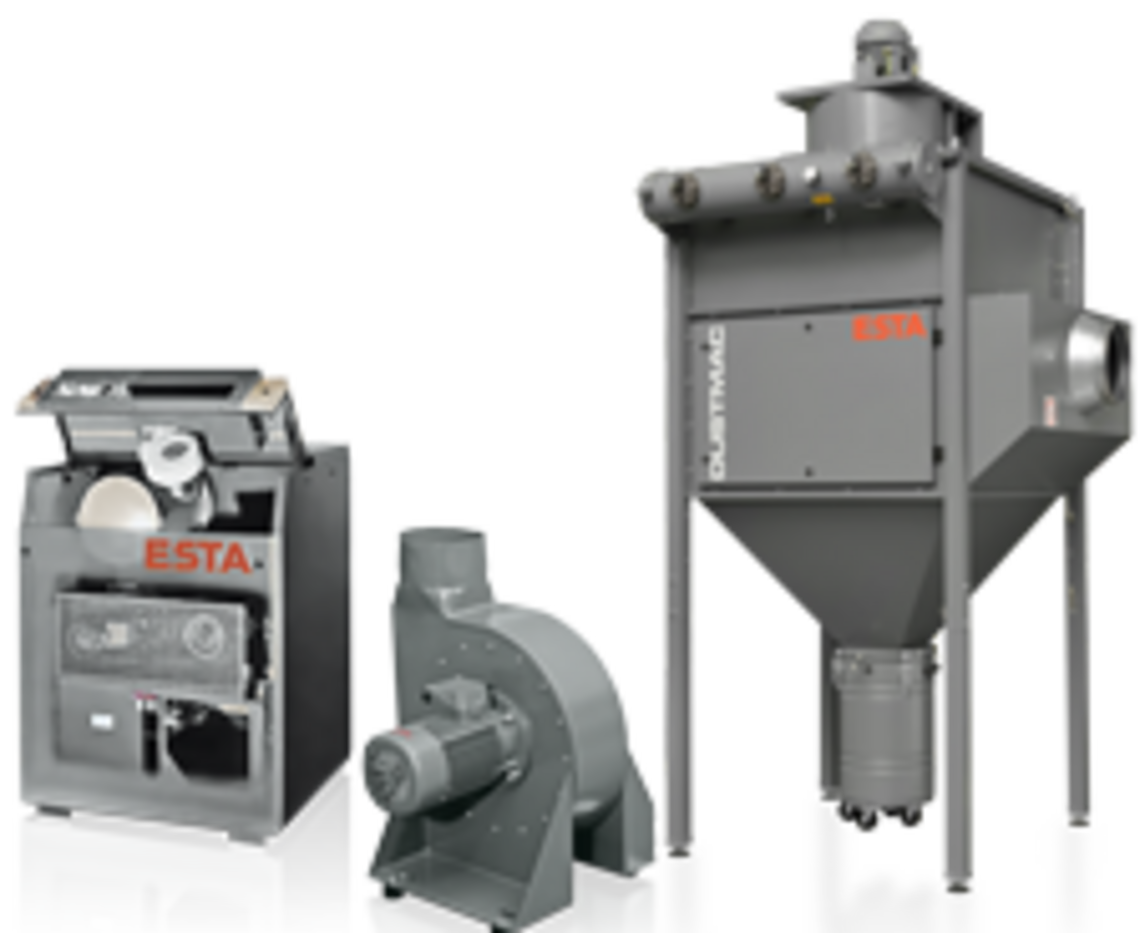

COMPONENTS OF A FIXED INSTALLATION EXTRACTION SYSTEM

Optimal selection and design of the system components for the respective application and the best possible coordination of the components result in a powerful extraction system. In addition to the specific application conditions, the valid regulations and guidelines must be observed when designing the extraction system.

An extraction system normally consists of the following components:

The filter unit is the core of an extraction system. The better the design and function of the filter unit, the better the separation result , i. e., the purer the air after the filtration process.

The filter unit consists of filter media or filter elements which are installed in the filter housing. Depending on the application, filter bags, filter cartridges or filter cassettes are used as filter elements in dry separation, and a water bath in wet filtration.

In dry separation, filter elements are usually cleanable. This ensures a constant extraction performance and low operating costs. To guarantee effective separation, the number and design of the filter elements must be matched to the medium to be extracted. The filter surface load (ratio of the filter area in relation to the extracted air volume per hour) must not exceed a defined limit value in order to avoid clogging of the filters.

Another important factor is the introduction of dusty air into the filter housing. The air should flow into the filter elements as evenly as possible whilst achieving a low upward flow speed of the air in the filter unit. Thus, the filter elements can be effectively cleaned during the extraction operation.

As a rule of thumb, the higher the quality of the filter material, the lower the flow speed in the filter unit and the filter surface load, and the more gentle the filter cleaning, the better the filter performs and the longer the service life of the filter elements. In practice this means low operating costs for the user.

The vacuum generator of a central extraction system ensures the required air volume flow. A distinction is usually made between low vacuum generators, medium vacuum generators and high vacuum generators. Medium vacuum and high vacuum generators are especially important for dust extraction systems. Medium vacuum generators are usually fans, which are used for applications where dusty air has to be collected and extracted. The negative pressure is around 8,000 Pa. at medium to high air volumes. Among the high vacuum generators are side channel compressors and rotary piston or screw compressors. They are used in applications where deposited material has to be "picked up" and transported through high-resistance pipelines. The negative pressure is high (from 140 mbar) with rather small volumes of air.

To achieve a satisfactory extraction result, it is important to select the appropriate vacuum generator and design it in accordance with the requirements of the particular application. Important factors are, for example, the number and simultaneity of the extraction points, the connection diameter at the extraction points, the required conveying speed of the material to be extracted, and the length of the extraction lines.

The vacuum generator is usually placed next to the filter unit. Due to increasing demands for low noise emissions, vacuum generators are installed in enclosures, which reduce the running noise and also serve as weather protection in an outdoor setting.

The dust discharge is located in a central extraction system directly below the filter unit and ensures that the particles separated from the air volume flow are transported out of the filter unit. As standard, collection bins, barrels or drawers are used, which are connected with the filter unit via a cone. It is important that the volume of the collection container is adequate for the dust that arises. If the collection containers are too small, emptying is often neglected and the separated debris accumulates in the filter unit, resulting in poor performance.

For hazardous substances, low-dust disposal of the separated dirt is necessary.

For large accumulations of dirt, automatic discharge elements such as rotary valves or discharge door valves or flaps are recommended, which convey the material continuously from the filter unit.

The control unit - often called the control cabinet - controls all the important functions of the central extraction system and ensures error-free operation. A large number of sensors now allows permanent monitoring of the most important system functions and virtually fully automatic operation of the system. For instance, the extraction performance can be adjusted to the current requirements according to the number of points to be extracted or also to the dust load in the air stream. This ensures low operating costs through low power and compressed air consumption. Pending maintenance or service work can now be determined based on the performance data - no longer, as in the past, only by means of a fixed number of operating hours.

The control unit of the extraction system in conjunction with more powerful sensor technology and sophisticated software makes it possible nowadays (and above all in the future) to adapt the system optimally to the relevant application.

OTHER COMPONENTS

In a broader sense these components belong to an extraction system:

- Extraction pipe

- Pre-separator

- Post-filter and heat recovery

- Return / exhaust duct

For satisfactory, long-term and economical functioning of an extraction system, it is essential that the components are optimally tailored to each other and to the respective application.

SUITABLE PRODUCTS

CONTACT

WE ARE HAPPY TO PROVIDE A PERSONAL CONSULTATION

We can adapt our exhaust installations to your needs. Tailor-made, modular and individual. Ask us!

Der Vakuumerzeuger einer Absauganlage sorgt für den erforderlichen Luftvolumenstrom. Unterschieden wird üblicherweise zwischen Niedrigvakuumerzeugern, Mitteldruckvakuumerzeugern und Hochvakuumerzeugern. Für Absauganlagen im Entstaubungsbereich sind vor allem die Mittel- und Hochvakuumerzeuger von Bedeutung. Mittedruckvakuumerzeuger sind i.d.R. Ventilatoren, die für Anwendungen eingesetzt werden, bei denen staubhaltige Luft erfasst und abgesaugt werden soll. Der Unterdruck bewegt sich bis ca. 8.000 Pa. bei mittleren bis hohen Luftmengen. Als Hochvakuumerzeuger werden Seitenkanalverdichter, Drehkolben- oder Schraubenverdichter eingesetzt, bei Anwendungen, bei denen abgelagertes Material „aufgehoben“ und durch Rohrleitungen mit hohem Widerstand transportiert werden muss. Der Unterdruck ist hierbei hoch (ab 140 mbar) bei eher kleinen Luftmengen.

Damit ein zufriedenstellendes Absaugergebnis erzielt wird, ist der passende Vakuumerzeuger auszuwählen und entsprechend den Anforderungen des Anwendungsfalls auszulegen. Wichtige Faktoren sind z.B. Anzahl und Gleichzeitigkeit der Absaugstellen, Anschlussdurchmesser an den Absaugstellen, erforderliche Fördergeschwindigkeit des abzusaugenden Materials, Länge der Saugleitungen, etc.

Die Aufstellung des Vakuumerzeugers erfolgt üblicherweise neben der Filtereinheit. Aufgrund der zunehmenden Anforderungen nach niedrigen Schallemissionen werden die Vakuumerzeuger in Einhausungen eingebaut, die das Laufgeräusch reduzieren – und bei Aufstellung im Freien auch als Witterungsschutz dienen.

Die Steuereinheit – oft Schaltschrank genannt – regelt alle wichtigen Funktionen der Absauganlage und sorgt für einen fehlerfreien Betrieb. Eine Vielzahl an Sensoren erlauben mittlerweile eine permanente Überwachung der wichtigsten Anlagenfunktionen und einen praktisch vollautomatischen Betrieb der Anlage. So kann z.B. die Absaugleistung den aktuellen Anforderungen entsprechend der Anzahl der abzusaugenden Stellen oder auch der Staubbeladung im Luftstrom angepasst werden. Das sorgt für niedrige Betriebskosten durch geringen Strom- und Druckluftverbrauch. Auch anstehende Wartungs- oder Servicearbeiten lassen sich heute anhand der Leistungsdaten und nicht mehr nur wie früher mittels fest definierter Betriebsstunden ermitteln.

Die Steuereinheit der Absauganlage in Verbindung mit leistungsfähiger Sensorik und hoch entwickelter Software ermöglicht heute und vor allem in Zukunft den optimal auf den Anwendungsfall abgestimmten Betrieb der Anlage.