WHAT IS DUST AND HOW DANGEROUS IS DUST AT THE WORKPLACE?

What exactly is dust? The beautiful golden flakes dancing in the sunshine through the air? The grey coating on shelves and desks that can drive you mad? Or the thick, fuzzy "woolly mice" under machines?

Whether on the construction site, in the wood workshop, in the bakery or during DIY, if you crush, drill, mill or grind raw materials, blow off dust with compressed air, pack, store, transport or mix dusty goods, tear up and empty bagged material or sweep up spilled material with a broom, you often disappear under a cloud of dust.

All that is dust. Dust is the finest particles floating in the air. These can come from everywhere: from space, from volcanic eruptions, from fires, from industry or from nature.

But dusts are also hazardous substances. This is often forgotten. The hazard spectrum ranges from purely mechanical irritation of the respiratory tract due to an acute irritative or toxic effect (e. g. chemical burns) to the development of chronic inflammatory processes and the formation of tumours. Most affected are the bronchi and lungs, but also the mucous membranes of the nose and eyes, the skin and other organs throughout the body.

WHAT EXACTLY IS DUST?

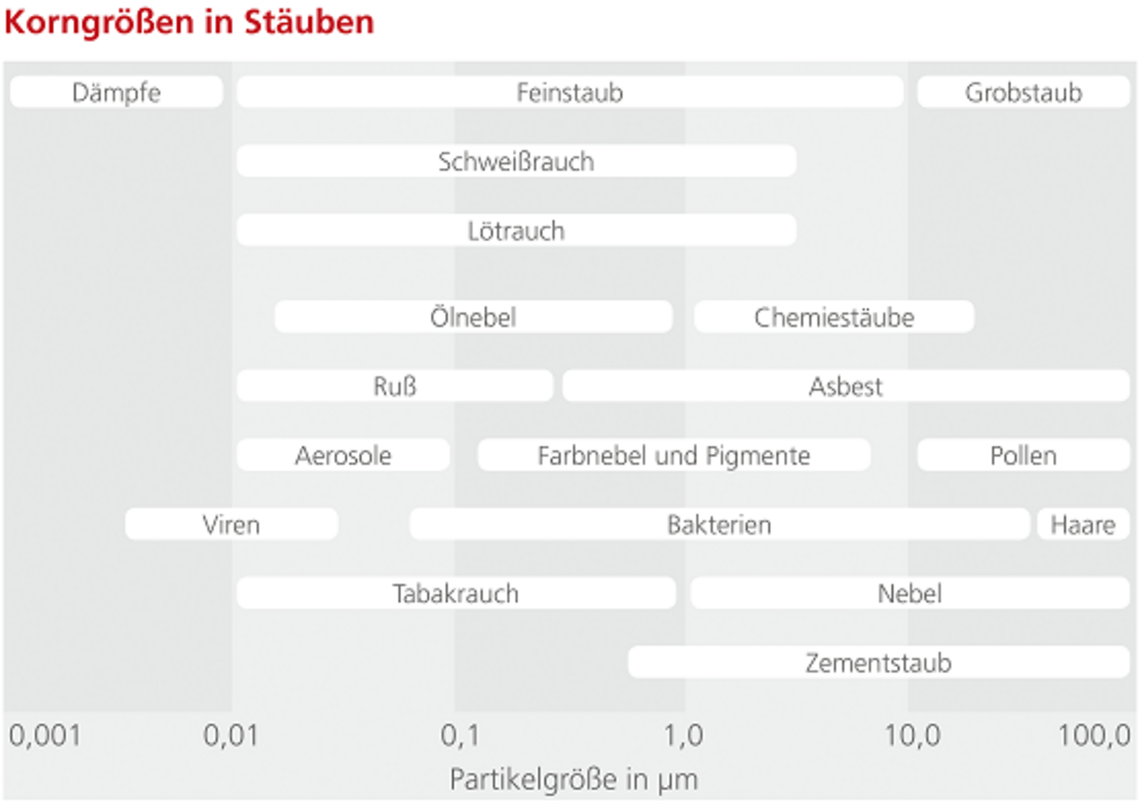

In general, dust is a collection of the tiniest invisible and visible particles that are in the air. The particle size of dust is measured in microns (μm), which are millionths of a metre.

HOW DOES DUST OCCUR?

Dusts consists of solid particles that are very finely dispersed in the air. They are produced by mechanical processing of solids (e. g. by crushing or surface treatment) or by whirling up (e. g. by blowing off with compressed air or dry sweeping with a broom) and thus enter the air we breathe. The solid particles formed by chemical or thermal processes (e. g. welding) and also very finely dispersed in the air are called fumes. They are also dusts in a broader sense.

WHAT ROLE DOES THE SIZE OF THE FINE DUST PLAY?

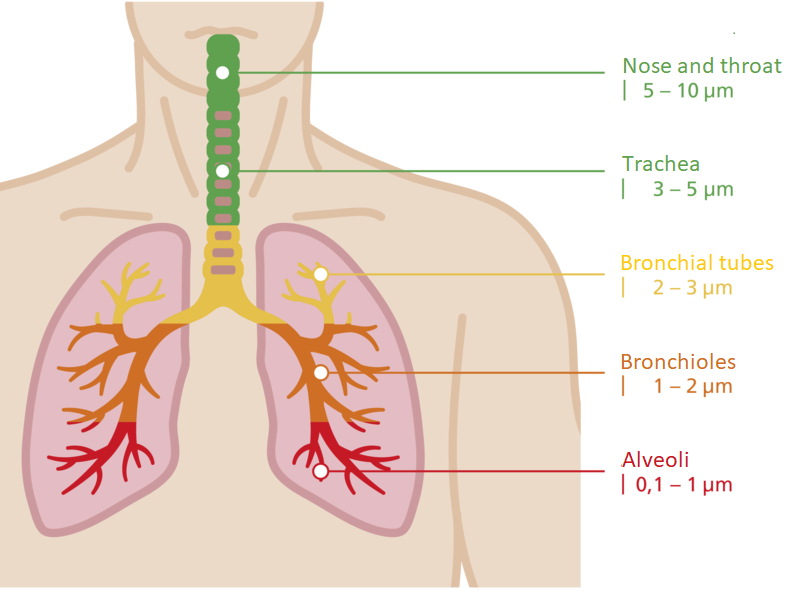

The smaller the particulate matter, the more damaging to health it is. The particles must be less than ten microns to enter the respiratory tract. At a size of 2.5 microns they reach the lungs. Ultrafine particles are almost as small as proteins, penetrate into the body cells and from there to the blood.

TYPES OF DUST

Several types of dust are defined in industry and legislation, such as: I, A and U dust.

Inhalable dust fraction

I-dust is the so-called "inhalable dust fraction". These are particles that can be inhaled through the mouth and nose. Frequently cited examples of this, apart from pollen, are cementdust or sand. The particles are generally smaller than 100 μm. 1 μm corresponds to 1 / 1,000,000 metres.

Alveolar dust fraction

A-dust is called the "alveolar dust fraction." These are particles that are small enough to penetrate the air sacs in the lungs (alveoli), including many fumes (such as welding fumes) and quartz dusts. The particles are smaller in size than 5 microns, so much smaller than I-dust particles.

Ultrafine or nanoparticles

Even finer particles are carried with U-dust - ultrafine or nanoparticles. This dust is smaller than 100 nanometres. 1 Nm corresponds to 1/1, 000,000,000 metre.

For the sake of completeness, fibres must not be forgotten. Amongst many others, these are among the types of dust which occur "by themselves" in nature, or in industry through manual or mechanical processing.

In nature, they are caused by erosion or flowering plants. They are distributed by the wind in the air and are thus a constant part of the air we breathe.

In industry, on the other hand, an attempt is made to collect the dusts or fumes produced during the machining of workpieces directly at source, in order to clear them from the air and not additionally pollute the air we breathe. Wherever it is not possible for technical process reasons to collect the dust directly, there is the option of installing what is called room ventilation.

WHY IS DUST HARMFUL?

IMPACT ON THE ENVIRONMENT

- Floating dust affects (and reduces) visibility.

- Dust represents an immediate danger to machinery and equipment and may be a cause of technical problems occurring, such as overheating electronics in the absence of ventilation, rapid wear of moving parts, poorly functioning sensors.

- Suspended dust settles over time as a (sometimes greasy) coating.

- This dust can return to the air due to the slightest air movement.

- Settling dust contaminates the products.

EFFECTS ON HEALTH

From a health point of view, particles of a particle size of less than 10 or 2.5 microns are the most significant.

The inhalable fraction is the most dangerous. It penetrates the alveoli and settles there, the gas exchange capacity of the lung is impaired, and inflammation occurs. Due to the poorer oxygen intake, the heart and vascular system are also indirectly overloaded.

The symptoms of zinc poisoning, also known as "brass founder’s ague", are, for example, a sweetish taste in the mouth, sweating, chills, body aches and a depressed mood. Zinc poisoning is caused by the inhalation of fumes generated during the galvanising or welding of galvanised material.

Contact with dust may be a source of disease if

- The concentration is very high,

- The dust particles are small enough to penetrate the trachea and bronchi deep into the lungs (alveoli),

- The shape of the particles (e. g. fibre) favours penetration,

- The dust contains toxic substances.

Possible consequences are coughing, shortness of breath, bronchitis, asthma, irritation of the skin and eyes.

Anyone who is exposed to large amounts of fine dust therefore has a higher risk of long term consequences such as cardiovascular diseases, severe damage to the respiratory system, damage to the nervous system, severe chronic lung diseases, lung cancer, heart attack or stroke, as well as allergies. These risk factors lower life expectancy.

WHERE IS THE DANGER HERE? HOW DANGEROUS IS IT FOR PEOPLE IN GENERAL?

This depends on where you work and what you work with. Not only toxic or ultrafine dusts, but any dust can lead to respiratory diseases at high levels.

The damaging effect depends on:

- The type of dust,

- The duration and amount of dust pollution,

- The place of deposition in the respiratory tract,

- The particle size.

Particularly dangerous is the intake of high amounts of dust over a short period of time or years of exposure to even small amounts of dust every day. Therefore, it is essential to extract dust efficiently under such conditions.

DUST AT THE WORKPLACE

LIMIT VALUES

The OELV (Occupational Exposure Limit Value) is defined as the maximum concentration of a pollutant in the air at the workplace.

HEALTH RISK AT THE WORKPLACE

In occupational safety, the health risks at the workplace are differentiated according to the size and shape of the particles as well as the material properties of the particles. The OELV is defined as the maximum concentration of a pollutant in the air at the workplace. This value is also referred to as the MWC (Maximum Workplace Concentration). By measuring the concentration of dust particles in the air at the workplace, it is possible to verify whether the OELV has been adhered to.

MEASUREMENT OF DUST POLLUTION

With the aid of dust measuring devices, it is possible to determine whether dust pollution at the workplace is compatible with health. The units automatically draw in air from the work environment and filter out the dust. The air concentration can be calculated based on the balanced amount of dust.

Measurements are carried out by the trade associations or accredited institutes (service providers). You are also welcome to contact us about this as well. Our sales staff will help you find the right contact person.

DUST CLASSES

LEGAL FRAMEWORK CONDITIONS AND CURRENT LEGISLATION

With the international standard IEC 60 335-2-69 dusts can be divided into three different dust classes: L, M and H.

Simple and harmless dusts such as house dust and materials such as sand, pebbles and earth.

Wood dusts of beech, oak, ash, pine, fir, birch and dusts of putties, fillers and paints and varnishes.

Harmful dusts when working with mould spores, mineral fibres, bitumen, artificial mineral fibres such as glass wool, plaster, cement, concrete, tile adhesives and paints such as latex and oil paints or quartz-containing materials.

The trade associations can provide on-site information on the classification and the amount of dust produced during operations.

The dust classes are indicated in MWC or OELV values. This value describes the maximum permissible concentration at the workplace (expressed in mg / m³), which does not cause illness after prolonged exposure (8 hours per day). The lower the MWC value, the more dangerous the dust.

MEASURES FOR THE PROTECTION OF HEALTH

- Conducting a risk assessment

- If possible, use low-dust products (e. g. low-dust tile adhesives, granules)

- Application of low-dust methods (e. g. wet processing, vacuuming)

- Observance of occupational exposure limit values (OELV) for dusts

- Organisational and technical measures have priority over personal protective measures

- Instruction of employees

- Do not dry sweep. Do not blow off with compressed air

- Wear protective clothing for dust-intensive activities and keep it away from work clothing

- Regular cleaning of the skin by washing or showering

- If dust pollution above the OELV cannot be excluded by these measures, wear personal respiratory protection

- Special occupational health check-ups after consultation with the company doctor

A SUITABLE EXTRACTION SYSTEM FOR YOUR DUST PROBLEM

For over 45 years, ESTA has been offering a wide range of innovative extraction products and tailor-made extraction solutions in the field of extraction technology for industry and commerce. Almost all types of chips and dusts can be separated with the appropriate type of filter. Find out about our comprehensive product range. We will find the right extraction solution for your dust problem as well.

CONTACT

WE ARE HAPPY TO PROVIDE A PERSONAL CONSULTATION

We can adapt our exhaust installations to your needs. Tailor-made, modular and individual. Ask us!