DUSTOMAT DRY

NEW DUST EXTRACTORS FILTERS WITH MAXIMUM FLEXIBILITY AND EFFICIENCY

Powerful, economical and quiet: the new compact dust extractors of the DUSTOMAT DRY series are suitable for nearly all purposes and effectively extract, among other things, the dusts and chips produced when processing metal and plastic. The modular housing concept enables the extraction system to be configured to fit precisely. Depending on the application, the filter package can be equipped with a separation efficiency of up to 99.995 %. The design of the system, for example the position of the intake connection piece, control cabinet and touch display, can also be flexibly aligned to the spatial conditions. The DUSTOMAT DRY devices are available in an ATEX-compliant design and will soon be available with the H or H3 test marks. They are suitable as single and multiple user extraction units for the medium performance range with air volume flows of 2,000 to 6,4000 cubic metres of air per hour.

Configurable dust extractor DUSTOMAT DRY for maximum safety | ESTA Extraction Technology

Thanks to the optimised aerodynamic design, the DUSTOMAT DRY dust extractors offer strong performance with higher energy efficiency at the same time. Thanks to the innovative DynamicPulse filter cleaning system, compressed air consumption is reduced by up to 50 percent compared to conventional filter cleaning systems. This also saves operating costs and extends the service life of the filter media. The extraction systems can also be operated in 100 percent air recirculation mode, which saves on heating costs in winter. The housing of the DRY devices is soundproofed and protects employees from additional noise emissions.

Gallery DUSTOMAT DRY

- Extraction of dry and free-flowing dusts and chips

- Depending on the design, can also be used for carcinogenic, flammable or explosive media

- Suitable for many applications, also for flying sparks

- Single and multi-user extraction for industry and commerce

- For direct extraction at processing machines

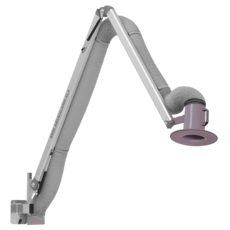

- For connection to extraction arms, extraction tables, extraction hoods as well as shorter pipe systems

- Sawing, separating, cutting

- Machining, milling

- decanting, filling, mixing

- grinding, deburring

- and much more.

- Metal dust

- Metal chips

- Chemical dusts

- CFRP/GFRP dusts

- Paper dusts

- and many more

Mobile installation

Smooth-running and flexible in use, making it suitable for frequently changing locations.

Stationary installation

Stationary extraction systems that can be connected next to processing machines.

DynamicPulse filter cleaning

The new generation of compressed air-operated cartridge filter cleaning. Saves up to 50% in operating costs.

Jet pulse filter cleaning

The Jet Pulse cleaning system automatically cleans the filter cartridges individually during and after suction operation.

Manual rotation filter cleaning

Thanks to a rotary nozzle connected to the compressed air network, the filter lamellas are blown through evenly.

ATEX CONFORM

For the extraction of explosive materials.

*The device is registered for testing.

DUST CLASS H

For the extraction of explosive materials.

*The device is registered for testing.

- Configurable: extraction power, filter package and system design

- Strong extraction power for optimal extraction results

- Aerodynamically optimised design for efficient air flow, resulting in low operating costs

- Low-noise system operation

- Recirculation / exhaust air operation possible

- Smooth-running castors

- Compact design

- Mobile dust collection drawer for easy disposal

- Sturdy, durable steel construction

- Intuitive operation via a convenient touch display

- High level of operation and maintenance friendliness

- Suitable for medium performance ranges from 2,000 to 6,400 m³/h

- Available in eight output levels

- Variable cleaning system, depending on the application

- 50 % compressed air savings thanks to innovative DynamicPulse filter cleaning system

- Integrated impact separator for pre-separation of coarse and heavy particles

- ATEX design

- Soon with IFA test certificate W3 for carcinogenic welding fumes (high-alloy steels)

- Pre-separator for sparks, chips and dusts

- HEPA H 14 filter (separation efficiency ≥ 99.995 %)

- Downstream activated carbon filter for odour neutralisation

- Version with frequency converter

- Stationary version

- Version with exhaust air connection piece

- Variable positioning of intake connection piece, touch display, control cabinet, etc.

- Other versions on request

Downloads & Data DUSTOMAT DRY

| DUSTOMAT DRY | 2000 | 2700 | 3300 |

|---|---|---|---|

|

Max. volume flow m³/h | 2,000 | 2,700 | 3,100 |

|

Max. negative pressure Pa | 2,400 | 2,900 | 3,400 |

|

Nominal power* kW | 2.2 | 3.0 | 4.0 |

|

Dimensions (L/W/H) mm | 1,630 x 840 x 1,430 | 1,630 x 840 x 1,430 | 1,630 x 840 x 1,680 |

|

Intake opening mm | 160 | 160 | 200 |

|

Sound pressure level dB(A) | 66 | 68 | 71,5 |

| DUSTOMAT DRY | 3400 | 3500 | 4500 |

|---|---|---|---|

|

Max. volume flow m³/h | 3,400 | 3,500 | 4,500 |

|

Max. negative pressure Pa | 2,900 | 4,500 | 3,400 |

|

Nominal power* kW | 3.0 | 5.5 | 4.0 |

|

Dimensions (L/W/H) mm | 2,120 x 1,110 x 1,950 | 1,630 x 840 x 1,680 | 2,120 x 1,110 x 1,950 |

|

Intake opening mm | 250 | 200 | 250 |

|

Sound pressure level dB(A) | 70 | 75 | 74 |

| DUSTOMAT DRY | 5800 | 6400 | |

|---|---|---|---|

|

Max. volume flow m³/h | 5,800 | 6,400 | |

|

Max. negative pressure Pa | 3,300 | 4,900 | |

|

Nominal power* kW | 5.5 | 5.5 | |

|

Dimensions (L/W/H) mm | 2,120 x 1,110 x 2,200 | 2,120 x 1,110 x 2,200 | |

|

Intake opening mm | 315 | 315 | |

|

Sound pressure level dB(A) | 74 | 72 |

*Mains voltage/Mains frequency: 400V/50Hz

| DUSTOMAT DRY | 2000 | 2700 | 3300 | 3400 |

|---|---|---|---|---|

| Standard version | X09700 | X09701 | X09702 | X09704 |

| DUSTOMAT DRY | 3500 | 4500 | 5800 | 6400 |

|---|---|---|---|---|

| Standardausführung | X09703 | X09705 | X09707 | X09706 |

Function overview of the ESTA control

- Optional: Stepless regulation of the extraction power

- Intuitive operation thanks to convenient touch display

- Display of the most important operating parameters (e.g.: status, operating hours, maintenance)

- Remote maintenance

- Timer

- Optional: Residual dust & filter breakage monitoring

CONTACT DUSTOMAT DRY

WE ARE HAPPY TO PROVIDE A PERSONAL CONSULTATION

We can adapt our exhaust installations to your needs. Tailor-made, modular and individual. Ask us!