ESTMAC D

DRY DUST EXTRACTOR ESTMAC D IS ECONOMICAL & QUIET IN OPERATION

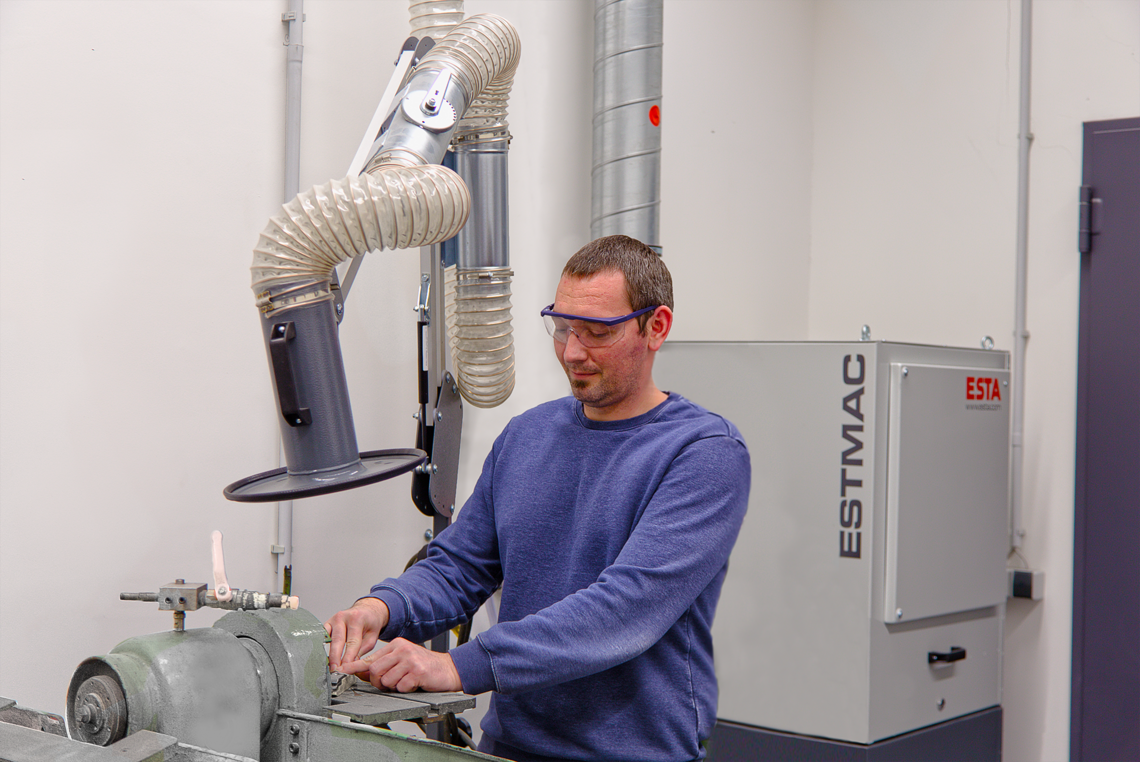

The dry dust extractors of the ESTMAC D series are suitable as a compact and affordable extraction solution for the lower to medium performance segment. The units extract dry and pourable dusts and offer a wide range of applications for many sectors: the stationary dust extractors can be connected directly to sanding blocks, saws or extraction tables for single as well as for multi-station extraction, and combined with an extraction arm for selective dust collection. Thanks to their compact dimensions, the ESTMAC D dry dust extractors can be flexibly installed in changing locations.

They are equipped with cleanable permanent filter cartridges of dust class "M", which correspond to a particle separation efficiency of 99.9%. The integrated pre-separator additionally extends the service life of the filter cartridges: it separates out coarse dirt and particles from the air intake in advance. it separates out coarse dirt and particles in advance from the air intake. This reduces the exposure of the filters, which only have to filter out the finer dust.

The mobile dust collection container can be used to dispose of the dirt easily and with little dust. The fan unit is flow-optimised and of soundproof design. This ensures a low operating noise.

Gallery ESTMAC

- Single and multi-station extraction systems

- Suitable for many applications

- For direct extraction on processing machines

- Sawing, cutting, separating

- Machining, milling

- Decanting, filling, mixing

- Sanding, polishing

- Metal chips

- Metal dusts

- Plastic dusts

- Plastic chips

- Mineral dusts

- Suspended particulate matter

- Dusts from composites

STATIONARY INSTALLATION

Stationary extraction systems that can be connected next to processing machines.

MANUAL ROTARY FILTER CLEANING

The filter blades are blown through evenly thanks to a rotary nozzle connected to the compressed air tank.

- Low operating and follow-up costs

- Low-dust disposal

- Suitable for use at different, changing locations

- Robust steel sheet construction for a long service life

- Low noise

- Use of permanent filter cartridges tested according to dust class "M"

- Very operation and maintenance friendly

- Integrated impact separator for coarse dirt

- Special design options

- Cleaning by means of a manual rotary nozzle

- Soundproof fan housing

- Clean air side high performance centrifugal fan

- Disconnectable, mobile dust collection drawer of approximately 40 l capacity

- Tilting device with gas pressure dampers

- Spark trap

- H post-filter

- Activated carbon filter

- Special RAL colour

Downloads & data ESTMAC D

| ESTMAC D | 1500 | 1800 |

|---|---|---|

|

Max. air flow m³/h | 1,500 | 1,800 |

|

Max. negative pressure Pa | 2,040 | 2,650 |

|

Nominal power* kW | 1.1 | 2.2 |

|

Main Filter elements piece | 1 | 2 |

|

Dust collection bin l | 40 | 40 |

|

Dimension (L/W/H) mm | 650 x 710 x 1.454 | 650 x 710 x 1.454 |

|

Sound level dB(A) | 71.3 | 73.3 |

*Mains voltage/Mains frequency: 400V/50Hz

| ESTMAC D | 1500 | 1800 |

|---|---|---|

| Standard design | 0991150 | 0991180 |

CONTACT ESTMAC D

WE ARE HAPPY TO PROVIDE A PERSONAL CONSULTATION

We can adapt our exhaust installations to your needs. Tailor-made, modular and individual. Ask us!